TNA project : Cooperation in Virtual Manufacturing Research using VirCA

Acronym : 80-Cooperation in Virtual Manufacturing Research using VirCA-Pter Galambos

Project Lead : Pter Pter Galambos From : Budapest University of Technology, Dept. of Manufacturing Science and Technology

Dates : from 26th November 2012 to 18th May 2013

Description :

Motivation and objectives :

VirCA (Virtual Collaboration Arena, www.virca.hu) is a modular, distributed framework for cooperative research that inherently involves 3D virtual reality. In the manufacturing science, the demand is emerging for complex, virtual manufacturing systems that can be reconfigured by a group of experts in order to optimize its performance. This kind of advanced visualization, simulation and layout design could significantly enhance the quality of the cooperation between the procurer and the consultant or between different branches of a large international company. Due to the diversity of immersive 3D infrastructures, the lack of modular, device independent VR frameworks obstructs the development of such cutting edge 3D cooperative design methods. My goal is to develop a device-independent, component based visualization layer for VirCA that supports a variety of CAVEs with different rendering, projection and head tracking solution. After this improvement, VirCA could be utilized in a wide range of virtual manufacturing and other cooperative projects that require immersive 3D visualization. justification of the choice of platform: The platform (VRCAVE at UNIKL) was chosen for two reasons. On the one hand is the hardware-setup comparable to the CAVE that will be the counterpart in Budapest on the other hand has UNIKL gathered first experience with the collaborative software tool VirCa. The Installation offers further the possibility to test out the multi-node rendering that is essential for a wide distribution of the software tool within the scientific community. The benefits, that can be created by device-flexible collaborative software toll will be evaluated on that basis. The first experiences of UNIKL with the software tool will further foster the usage and the identification of the collaborative potential. Even after the physical attendance can results be generated by using and testing the distance collaborative approach. I am already in contact with the selected host organization (University of Kaiserslautern, Institute for Manufacturing Technology and Production Systems - VRLAB) and they are willing to see me at their laboratory in case of this proposal succeeds.

Teams :

Department of Manufacturing Science and Technology (DMST) has 19 academic staff, 7 researchers (4 of them working full time for EC-funded research projects), and 6 post-graduate students. The department is active in the areas of material science; planning, simulation, diagnosis and monitoring of technological processes; tribology; theory of metal cutting; design and application of machine tools; assembly automation; robot application and gripper design; service robots including medical robotics, testing and control of robots; CAD/CAM; quality assurance; scheduling control and simulation of manufacturing systems; and virtual reality in manufacturing. The department took part in 7 FP4 and 4 FP5 projects and currently is taking part in 7 ongoing FP6 projects and 4 nationally-funded projects.

Dates :

starting date : 26 November, 2012

ending date : 18 May, 2013

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/UNIKL-VRCAVE.DE.html

Recordings & Results :

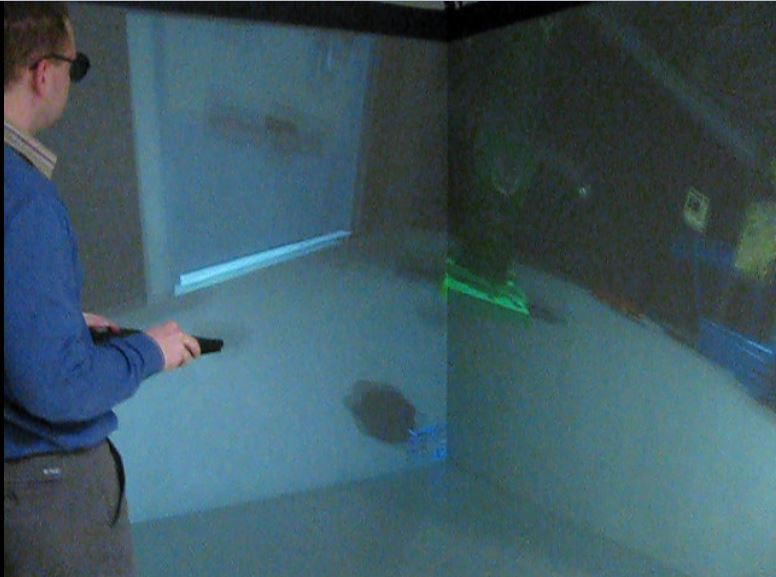

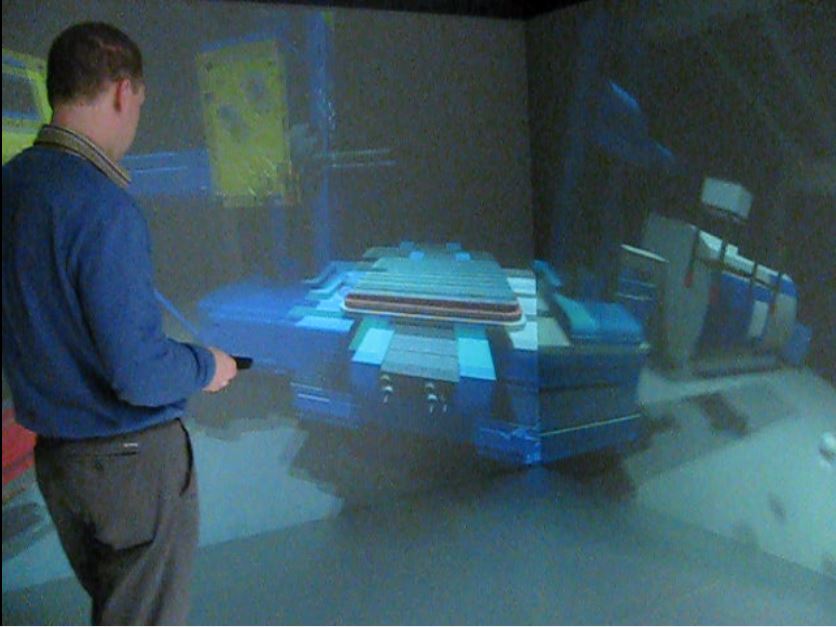

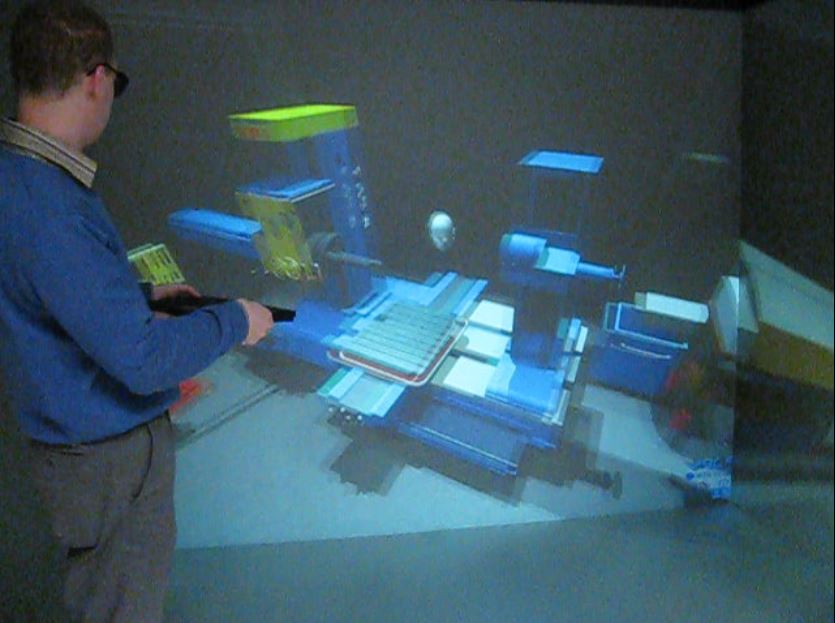

During the TNA the VirCA NET framework developed at University of Budapest was deployed to the UNIKL CAVE. For the first time a multi-node rendering approach was used for VirCA. The optical tracking system was basically implemented. The capabilities to support distance collaboration within full-immersive, virtual environments have been evaluated and tested among a typical, industrial use-case.

Conclusions :

The TNA aimed at the deployment of VirCA at the UNIKL CAVE and the extension of the VirCA idea towards the production engineering domain. Therefor the VirCA setup was adapted to handle the visualization cluster of UNIKL which is composed out of 9 single PCs (one controller and 8 rendering nodes). After that the link between UNIKL CAVE and the TNA applicants CAVE was established. A bi-directional connection could be established to share a joint virtual environment between the two locations. This shared environment was used to validate the concept of spatially distributed factory planning. Both planning participants could manipulate and evaluate the factory layout, independend from their spatial location. In the provided use-case a central planning specialist and a local worker could work together, to optimize the location of a new implemeted machine depending on central planning methods and local constraints.

Few images :

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044