Title : Assembly simulation using haptic devices

Project Lead : IACOB Robert From : Politehnica University (None)

Dates : from -- to 2014-11-28 14:15:51

Description :

Motivation and objectives :

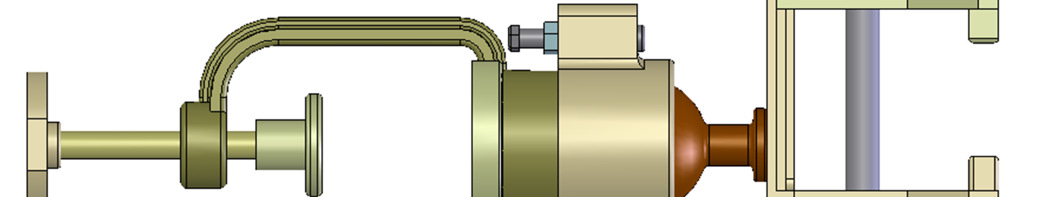

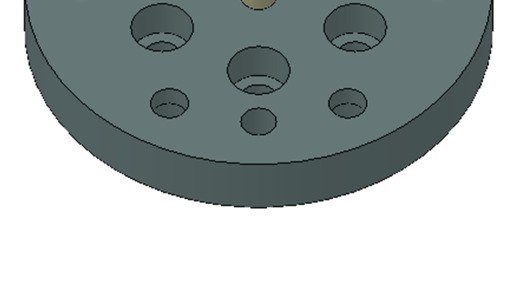

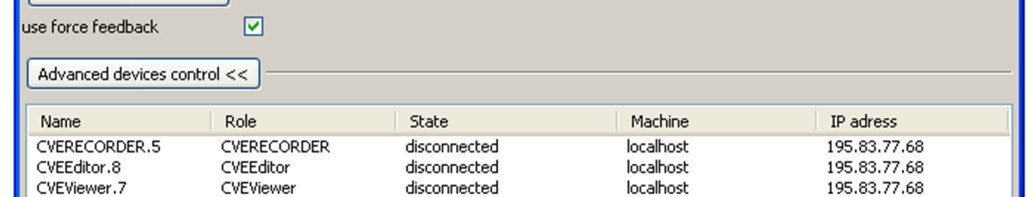

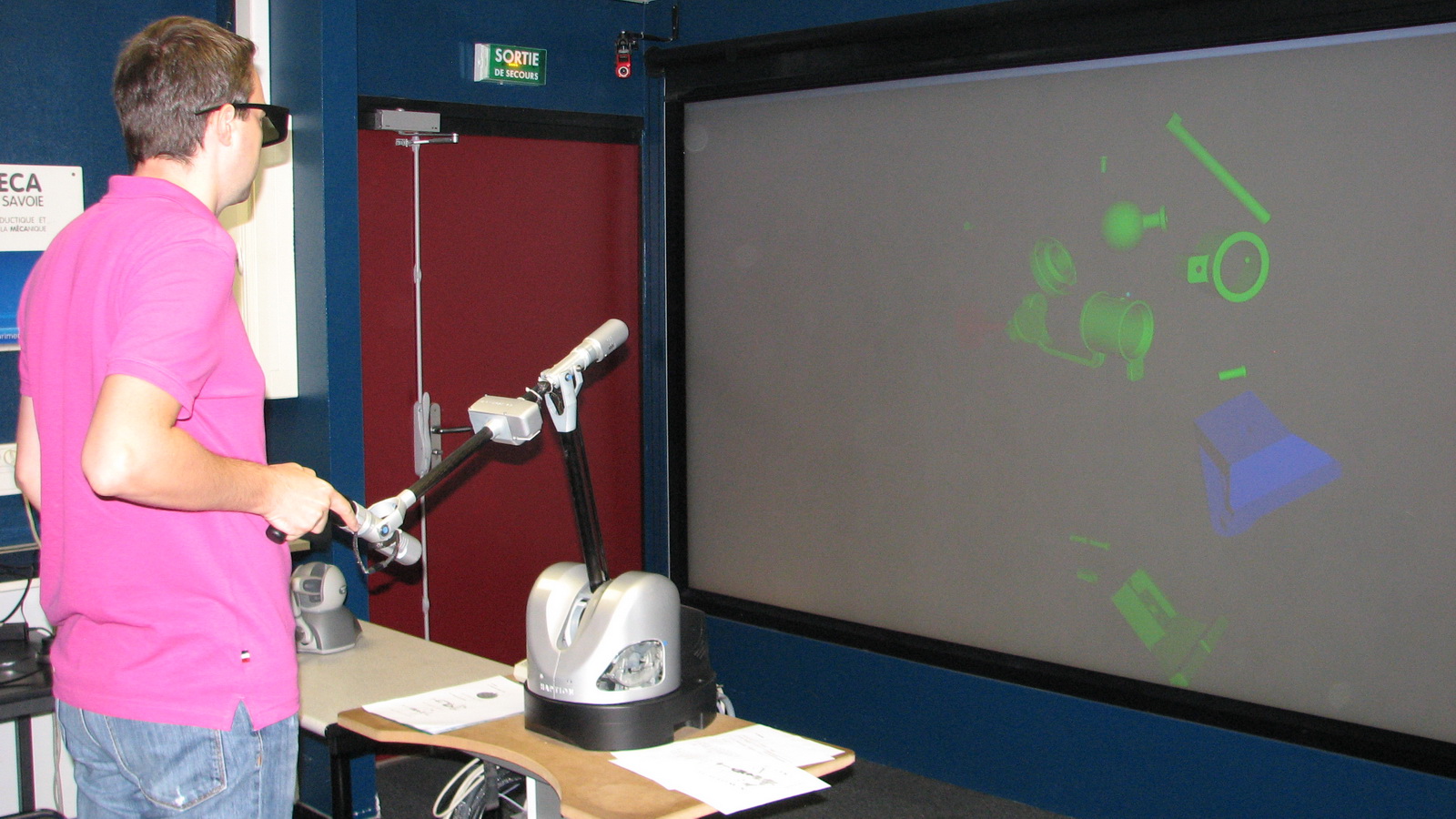

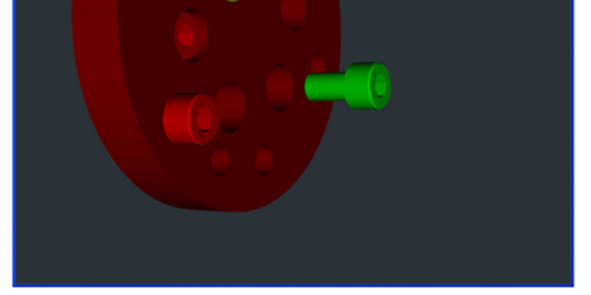

Optimization and realistic virtual simulation of the Assembly and Disassembly (A/D) process represent important research subjects, considering the important role played by these operations in the initial stages of the product design, as well as in the fabrication, ergonomics, training, service or recycling stages. Literature reports many methods used for analysis and different simulation applications based on assembly connection concept or which use information referring to components mating. Recently, Virtual Reality (VR) environments have significantly evolved towards the A/D simulation, highlighting new requirements for the preparation stages and their integration. Many of these platforms use haptic feedback and are facing difficulties while simulating the insertion/extraction operations such as removing cylinders from holes. In this context, the main objective of this research is to improve the A/D process simulation through better haptic devices integration. To this end, a series of tests with a 6DOF haptic device are necessary. Another objective is to evaluate a mobility module able to model contact relations between elementary components of a product and to determine the relative mobilities of the assembly components. This one can efficiently contribute to the real-time simulation process, when it is performed with 6DOF haptic devices, by reducing the complexity of the collision detection algorithms.

Teams :

The Virtual Enterprises Management and Engineering Research Center PreMinV, established in 2003, is a professional and independent supply organization, non-political, non-governmental, which is intended for research activities, for consultancy and training in virtual industrial enterprises management and engineering field, whose existence is imposed by global manufacturing and competition, under the impact of the new informational technology and communication.

Dates :

starting date : 29 June, 2014

ending date : 19 July, 2014

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/MEXICO.FR.html

Recordings & Results :

Optimization and realistic simulation of the Assembly and Disassembly (A/D) process represent important research themes, considering the important role played by these operations throughout the Product Life-Cycle (PLC). In recent years, Virtual Reality (VR) technology has evolved to a new level of sophistication. Now it combines several human-computer interfaces in order to provide various sensations and to enable users to become more immersed in a computer-generated platform. Thus, Virtual reality Environments (VE) are frequently used to simulate operations from different domains of activity, one of them being the A/D process. Many of these applications use haptic feedback and are facing (major) difficulties simulating some (detailed) operations e.g. insertion/extraction.

Conclusions :

In order to have a meaningful evaluation, different types of assessments were deployed: ? Real-time quantification: ? number of assembled components (3 DoF vs. 6 DoF) ? average time for a component assembly (3 DoF vs. 6 DoF) ? average number of clicks for selection (3 DoF vs. 6 DoF) ? Questionnaires: ? pre-activity ? post-activity questionnaire (3 DoF and 6 DoF) ? final questionnaire Each test session was recorded. Thus, three types of elements were measured (extracted) in real-time. This data will be concatenated with the questionnaires results. The main part of the questionnaires was based on a standard Likert scale: 1 absolutely not to 5 absolutely. Thereby, the questionnaires answers provided a fast evaluation of the users satisfaction when using the application: ease of use, usefulness of stereoscopic view, utility of the haptic cues etc. and a comparison of the two haptic devices: Haption Virtuose 6D and Geomagic Omni. In the near future, more details, relevant data and conclusions will be presented through different scientific articles.

Project Images :

Other project resources :

Visit report TNA22.pdf

CVE097 - 6dofViseSter.MTS

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044