Title : AR4CAD

Project Lead : Claudio Salati From : T3LAB (Italy)

Dates : from 2014-10-27 16:19:30 to 2015-02-09 18:58:50

Description :

Motivation and objectives :

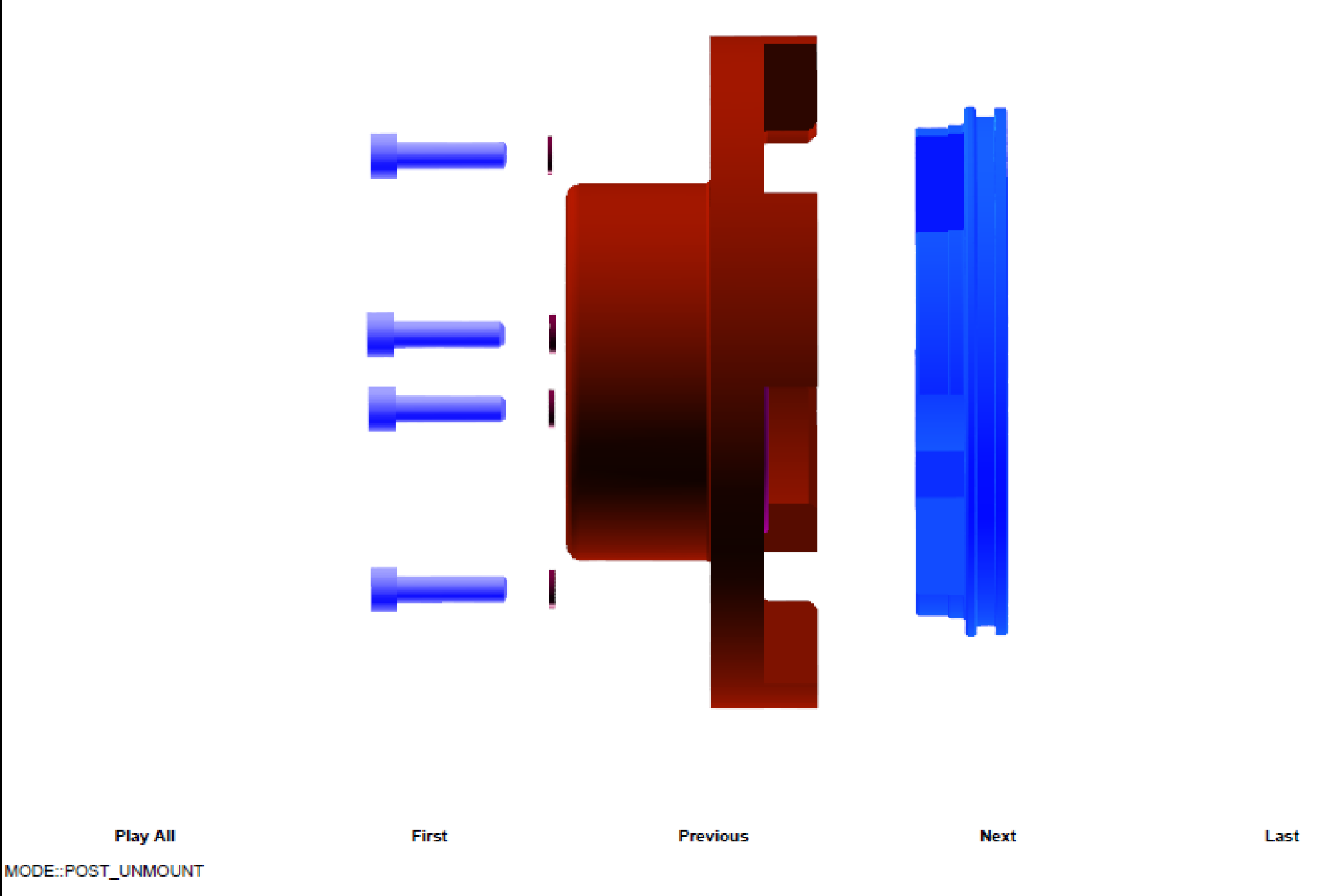

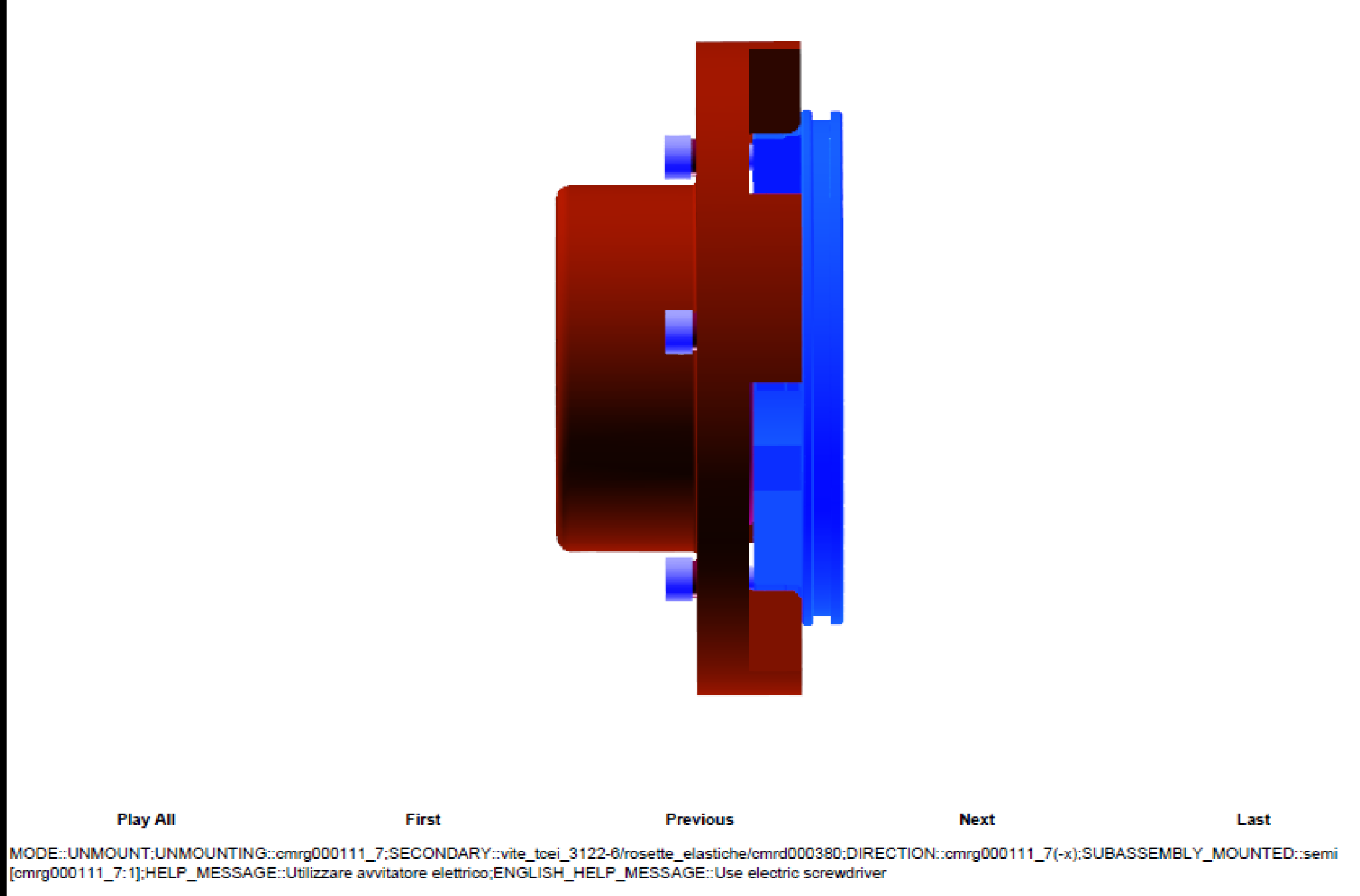

The project aims at developing an augmented reality (AR) environment in which to simulate maintenance tasks within a complex engineering context. An original AR architecture (AR4CAD) will be utilized in order to create a unique environment whose features are able to satisfy requirements for maintenance tasks. The architecture is based on complex hardware and software technologies available at the Operations Excellence laboratory at Cranfield. A case study will be realized in AR4CAD, regarding the replacement of a mechanical component in an assembly, an issue that is relevant to any industry. The focus will be on small objects.

Teams :

The main technological focus of the group that deals with the use of AR in the industrial environment is computer vision in industrial automation. The group has dealt with problems of quality inspection, pick-and-place, object reconstruction and colorimetry, and has built 2D and 3D applications.

Dates :

starting date : 12 January, 2015

ending date : 16 January, 2015

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/OPSIMLAB.GB.html

Recordings & Results :

the project aims at developing an augmented reality (AR) environment in which to simulate maintenance tasks within a complex engineering context. An original AR architecture (AR4CAD) will be utilized in order to create a unique environment whose features are able to satisfy requirements for maintenance tasks. A case study will be realized in AR4CAD, regarding the replacement of a mechanical component in an assembly, an issue that is relevant to any industry. The focus will be on small objects. The project wants to demonstrate the important potentials offered from AR techniques in industrial applications, in particular, for maintenance tasks in various industries ..

Conclusions :

AR application for Assembly workflow developed. The results of our work are: a storyboard created with Inventor Publisher using the new frames UNMOUNT and REPLACE. This storyboard contains the instruction for a replacement job of a simple assembly. an XML file obtained compiling the storyboard. a video of the execution of the replacement job driven by our augmented reality software.

Project Images :

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044