Title : Design of a Virtual Reality Environment for MAintainability TEsts and MAnufacturing Systems Simulations

Project Lead : Adelaide Marzano From : Queen's University Belfast (None)

Dates : from 2014-09-05 12:02:23 to 2014-11-28 11:37:41

Description :

Motivation and objectives :

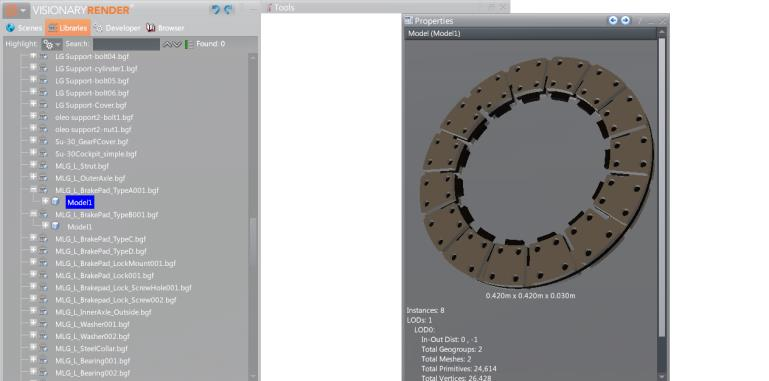

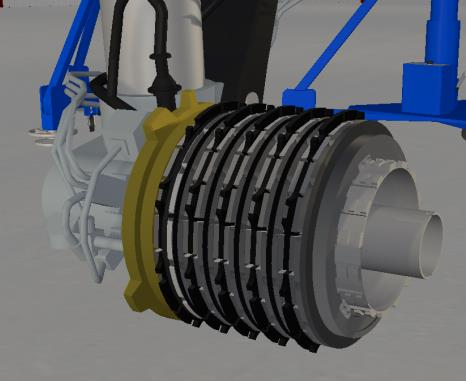

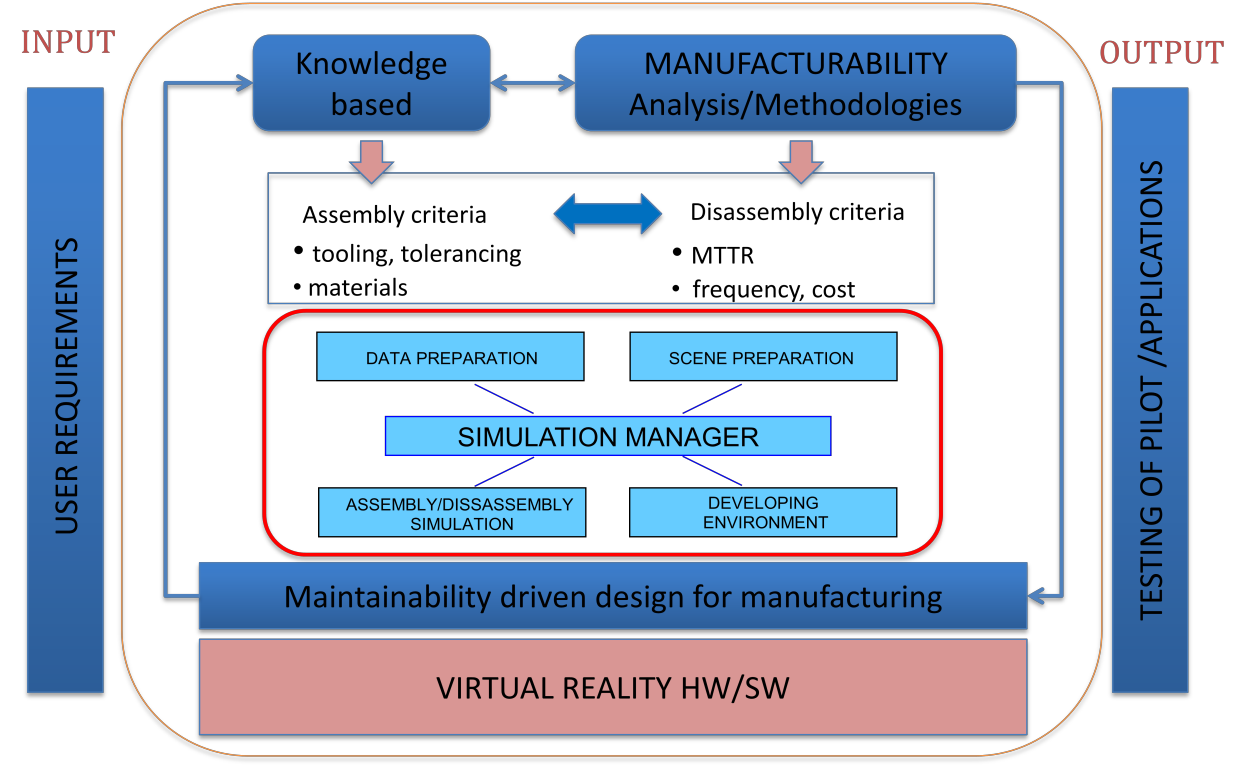

the project aims at developing a Virtual Reality environment in which to simulate maintainability tests and manufacturing systems. An original VR architecture (MATEMASYS2) in order to create a unique environment whose features are able to satisfy requirements both for Virtual Maintenance and Virtual Manufacturing tasks is conceived. The architecture is based on complex hardware and software technologies available at xxxxxxxxxxxxxxxxxxx.Two case studies to be realized in MATEMASYS, regarding the maintainability of a complex assembly and the simulation of a work cell, are proposed.

Teams :

With a strong background in digital manufacturing methods and industrial collaboration, the Manufacturing group within the Aerospace and Manufacturing cluster focuses on the development and application of advanced simulation tools and virtual environments for improved product and process design concurrency for digital: manufacture, assembly validation & automation, product certification, service performance, decommissioning & recycling. Our work in this area has included rigorous evaluation and development of digital manufacturing capability carried out in partnership with industry (Bombardier, BAE systems, Airbus). Specific areas of research have focused on the quantification of the benefits of the technology in terms of organisational learning, automatic time and cost generation and the extension of key functionality beyond manufacturing processes into the broader product lifecycle. Current and future work includes the addition of advanced engineering capability within PLM tools to facilitate the use of more realistic part forms for advanced composite assembly processes, the application of simulation methods for improved integration of automated systems and lifecycle planning for advanced transport systems.

Dates :

starting date : 20 October, 2014

ending date : 24 October, 2014

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/OPSIMLAB.GB.html

Recordings & Results :

To develop an original VR architecture (MATEMASYS2) in order to create a unique environment whose features are able to satisfy requirements for Virtual Maintenance and Virtual Manufacturing tasks is conceived. The architecture is based on complex hardware and software technologies available at the Operations Excellence laboratory at Cranfield. A case study to be realized in MATEMASYS2, regarding the maintainability of complex assemblies is proposed.

Conclusions :

The present work wants to demonstrate the important potentialities offered from VR techniques in industrial applications, in particular, for maintainability tests on complex assemblies and for the simulation of manufacturing systems. Obtained results not only provide a valid answer to the design questions in the field of maintenance and manufacturing systems simulation, but they make objective the effective applicability of the proposed methodology: in spite of the subjective character of the approach to the simulation, based on the direct manual interaction, the information collected in the case studies, allow to grant the feasibility of tasks and to individualize the design parameters on which operating to better answer the functional requirements and, finally, to improve the design.

Project Images :

Other project resources :

MATEMASYS2.pdf

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044