Title : Modelling 6-DOF parallel kinematics manipulator with Matlab-Simulink software and its visualisation in Virtual Reality environment

Project Lead : Zoran PANDILOV From : Faculty of Mechanical Engineering, University "Sv. Kiril i Metodij" -Skopje, Republic of MACEDONIA (Republic of MACEDONIA)

Dates : from 2014-07-11 19:53:07 to 2014-11-28 15:09:26

Description :

Motivation and objectives :

Parallel kinematics manipulators have attracted the attention in research institutions and industry due to their high theoretical dynamics potential, structural rigidity and high accuracy due to the closed kinematic loops and no error accumulating characteristics. Parallel manipulator also could be named as hexapod, a Stewart platform, Gough platform, Stewart-Gough platform, a parallel kinematics machine (PKM) or a parallel robot. Parallel kinematics manipulators are applied in different mechatronic systems, like robots and CNC machine tools. 6 DOF parallel kinematics manipulators are very complex devices because the position and orientation of the tool or of the platform is dependent on the positions of each limb (leg). For 6 DOF parallel kinematics manipulator it is very difficult to calculate the forward kinematics. Designer of such kind of manipulator must consider the manipulator dynamic too, which could be great problem in early, conceptual design phase. Precise calculations are time consuming and there is always a risk of some mistakes. Using simulation and visualisation environments, like Matlab-Simulink and EON Studio software, is very helpful in checking the correctness of the 6 DOF parallel kinematics manipulator structure. The Matlab-Simulink program with extension toolbox SimScape allows to implement the complex models of the mechanisms and perform simplified visualisation. These facilities could be useful especially in the beginning phase of the design, as well as, during the whole design process. It is possible easy to modify the model and instantly check the results. The designer could ensure that the different type of components (actuators, joints, sensors, etc) are selected properly. SimScape allows to perform simplified visualisation, while EON Studio is environment specially for visualisation purposes. The project assumes two main objectives: 1. building Matlab-Simulink dynamic model of the 6 DOF parallel kinematics manipulator with the aid of the new facilities and 2. visualisation of the work and the movement of the manipulator in Virtual Reality system, like EON Studio software. The purpose is to use new techniques in modelling of such complex systems and improve the models quality and accuracy. The prepared model will be more complex than these obtained by classical methods and approach and will allow to improve the design of the 6 DOF parallel kinematics manipulator without manufacturing the physical prototype. The project will focus mainly on the mechanical system of the parallel kinematics manipulator, because the planned visit is only two weeks (10 working days).

Teams :

I belong to the Chair of Production Processes and Systems: The main research interest of the Chair is focused on: Flexible automation, CAD / CAM / CAE / CAPP, CIM, New materials (Composites and Polymer Concrete), Artificial Intelligence and Expert Systems. The Chair has participated in many International (DAAD, CEEPUS, TEMPUS, JICA, etc.) and national projects.

Dates :

starting date : 14 October, 2014

ending date : 27 October, 2014

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/VDS.PL.html

Recordings & Results :

6 DOF parallel kinematics manipulators are very complex devices because the position and orientation of the tool or of the platform is dependent on the positions of each limb (leg). For 6 DOF parallel kinematics manipulator it is very difficult to calculate the forward kinematics. Designer of such kind of manipulator must consider the manipulator dynamic too, which could be great problem in early, conceptual design phase. Precise calculations are time consuming and there is always a risk of some mistakes. Using simulation and visualisation environments, like Matlab-Simulink and EON Studio software, is very helpful in checking the correctness of the 6 DOF parallel kinematics manipulator structure. The Matlab-Simulink program with extension toolbox SimScape allows to implement the complex models of the mechanisms and perform simplified visualisation. These facilities could be useful especially in the beginning phase of the design, as well as, during the whole design process. It is possible easy to modify the model and instantly check the results. The designer could ensure that the different type of components (actuators, joints, sensors, etc) are selected properly. SimScape allows to perform simplified visualisation, while EON Studio is environment specially for visualisation purposes.

Conclusions :

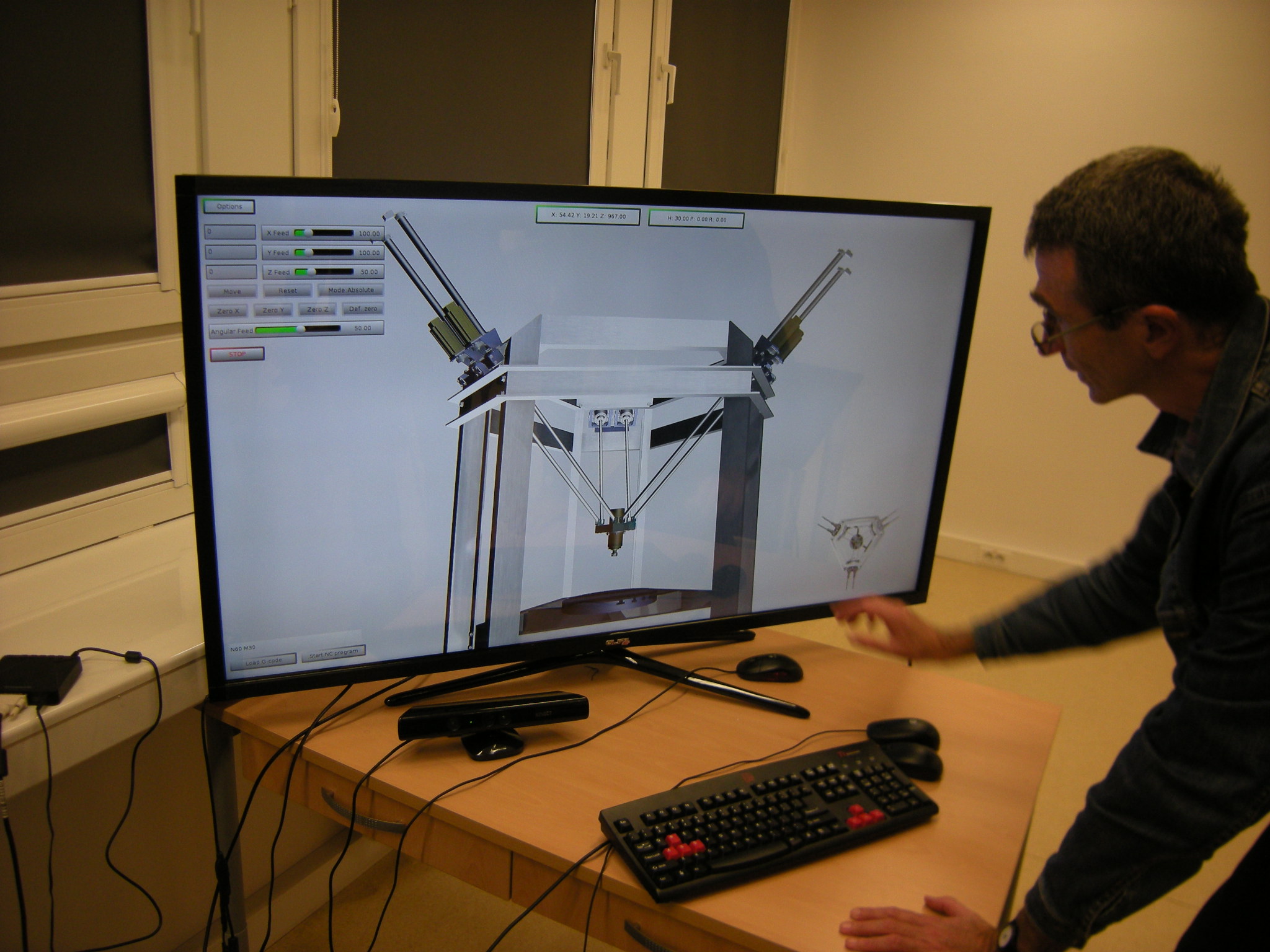

The research was very complex and divided in two phases. The first phase was modelling of the very complex model of the 6 DOF parallel kinematics manipulator which consists of several subsystems: trajectory generator model, controller and servo system model for each strut (leg) and mechanical structure model which consists of large number of different mechanical parts. The modeling was done with Matlab-SIMULINK and SimMechanics Toolbox. The SimMechanics Toolbox allowed us to use the complete CAD model of the geometry of the 6 DOF parallel kinematics manipulator (Hexapod CNC machine tool) in modeling and automatically calculating the selected properties. Using the Simulink model for the servo system for controlling of each strut (leg) of the hexapod the influence of changing and optimization of several servo system parameters (position loop gain Kv, proportional gain Kp of the velocity controller, integral gain of velocity controller-Tn, electrical drive time constant Te, total moving mass m, sampling period Ts, etc.) on positioning accuracy (length) and dynamic stiffness were simulated, tested and validated. The ready Matlab-Simulink and SimMechanics models were initially visualized in the Matlab program, but they were very simplified, comparing their visualization in Virtual Reality EON Studio program. The second phase of the research was visualization of the whole complex model of 6 DOF parallel kinematics manipulator (Hexapod CNC machine tool) developed in Matlab-Simulink and SimMechanics in Virtual Reality system with EON Studio software. The using of EON software significantly improved the model and the visualization quality. With the visualization we were able to simulate the real work and movement of the whole 6 DOF parallel kinematics manipulator (Hexapod CNC machine tool).

Project Images :

Other project resources :

Pandilov_2.PDF

Prof.Pandilov-FINAL REPORT-Visionair-Project-185-Poznan-October-2014.doc

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044