Title : Visualization-enhanced methods in the design of transfer lines

Project Lead : Olga Battaia From : Ecole des Mines de St Etienne (None)

Dates : from 2014-06-26 14:35:13 to 2015-02-09 19:00:22

Description :

Motivation and objectives :

The approaches devoted to the design of transfer lines must take into consideration a large amount of factors, e.g., the design of the layout, the optimization and balancing of the transfer line configuration and the associated performance. These aspects must be jointly addressed in order to achieve a near-optimal configuration of the line The objective of the project is to use the Virtual Factory Framework based approaches to configure and visualize a production system, developed by the researchers at ITIA-CNR and Politecnico di Milano with an optimization approach to configure transfer lines developed by the researchers of Ecole des Mines de Saint-Etienne via a collaborative work . The coupling of optimisation-simulation-visualization techniques aim to first optimize the system configuration using available data and the 3D visualization capability, then simulate its behaviour and enrich the optimisation model with the simulation results if necessary repeat the optimisation cycle.

Teams :

The DEMO (Decision in the Enterprise : Modeling, Optimization) Department of the Henri Fayol Institute brings together 20 researchers in the field of applied mathematics for modeling and decision-making. The research domains of DEMO are the following: the development of new products, of new manufacturing processes and systems using mathematical models and optimisation methods.

Dates :

starting date : 23 October, 2014

ending date : 31 October, 2014

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/VFACTORY.IT.html

Recordings & Results :

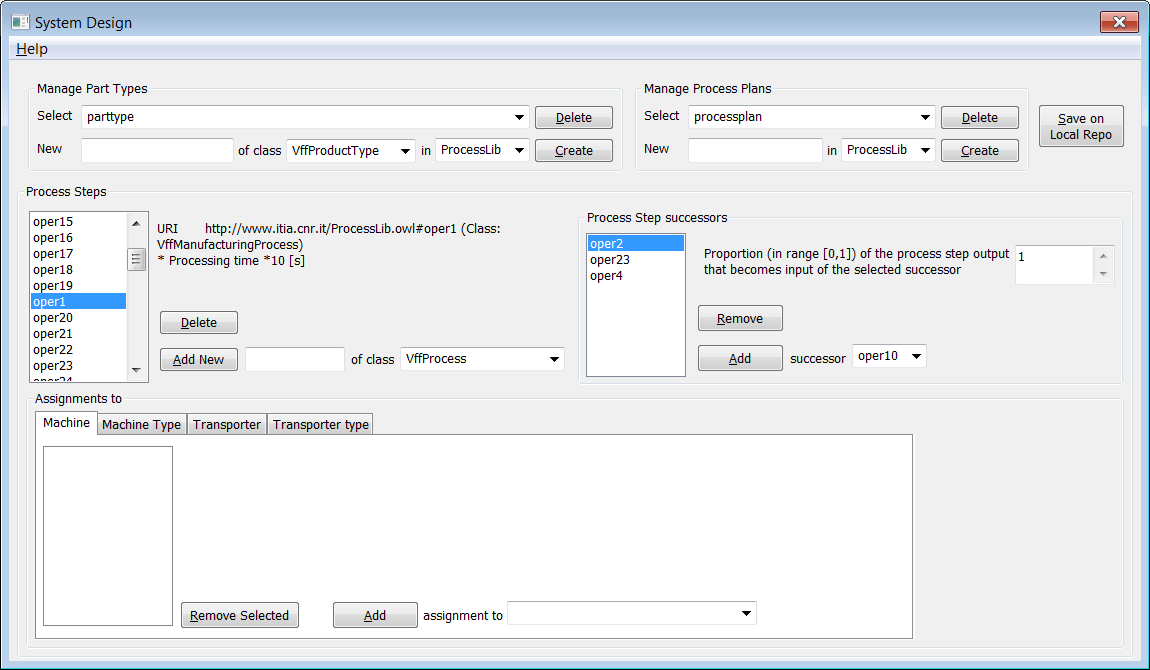

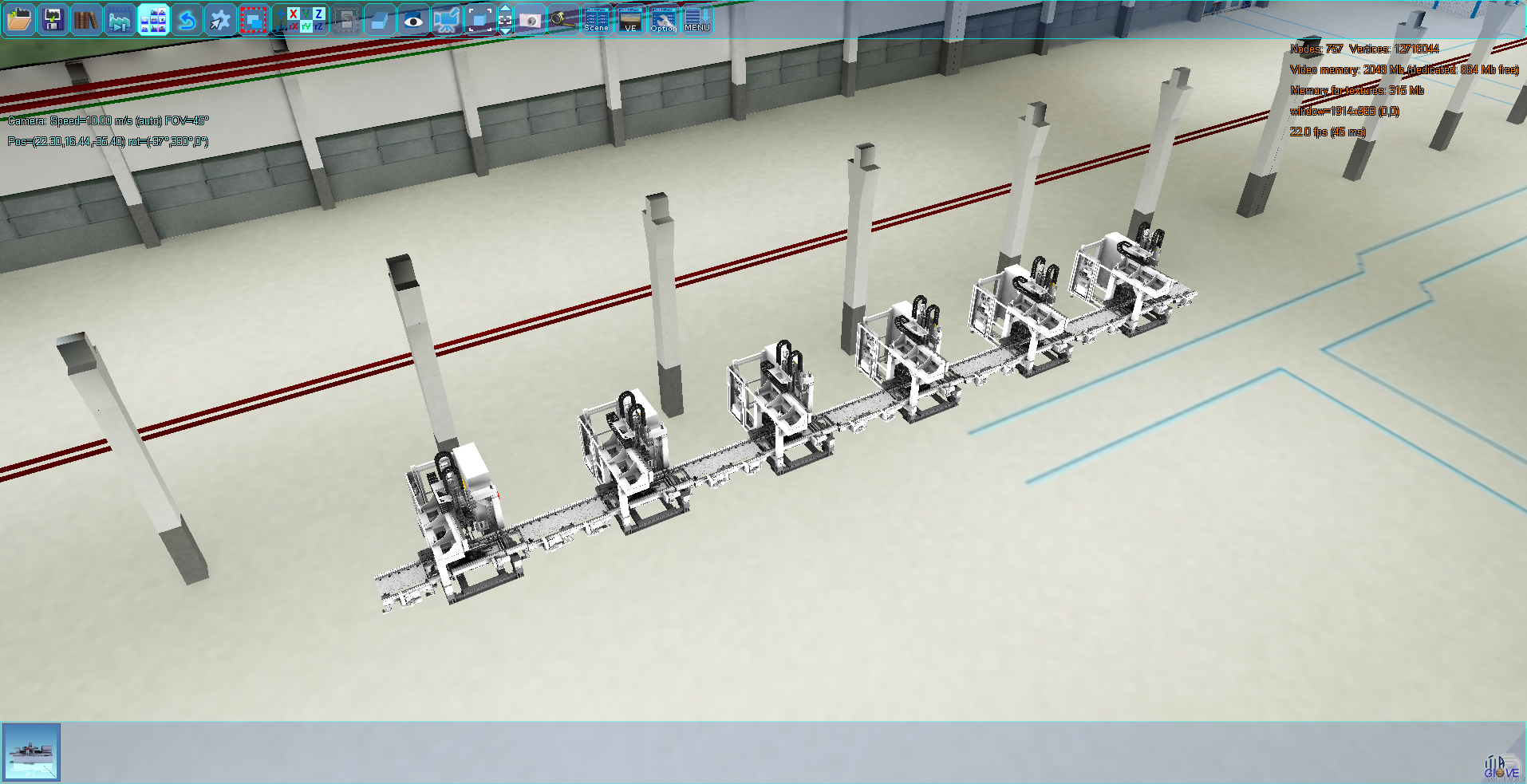

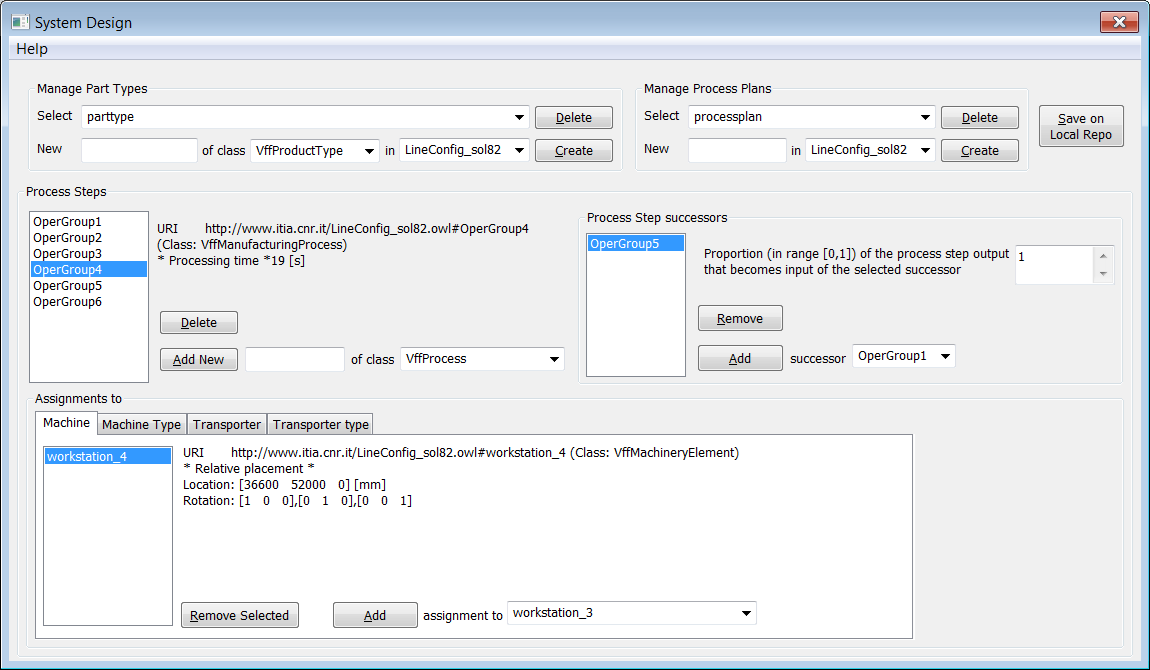

The goal of the work was to study how VR technologies can be exploited to support the design of manufacturing systems, in particular transfer lines. The visiting researcher, Prof. Battaa, has a long experience in the development of mathematical methods for the design of transfer lines taking into consideration the optimization and balancing of the transfer line configuration and the associated performance. However, the results of these optimization methods cannot be easily visualized to check also their feasibility with respect to the factory layout. Therefore, the objective of the project was to give the results of an optimization method (developed by the researchers of Ecole des Mines de Saint-Etienne) as input of visualization and performance evaluation tools (developed by the researchers at ITIA-CNR and Politecnico di Milano) in a collaborative by using a Virtual Factory Framework (VFF)-based approach. The coupling of optimisation-simulation-visualization techniques aim to first optimize the system configuration using available data and the 3D visualization capability, then simulate its behaviour and enrich the optimisation model with the simulation results if necessary repeat the optimisation cycle.

Conclusions :

After analysing the available optimization methods to design a transfer line, the attention was focused on the data generated as output by such methods. These data were mapped to the ontology-based data model that represents a component of the Virtual Factory Framework; a converter was developed according to this mapping, so that the results of the optimization methods could be used as input by other software applications without needing to develop peer-to-peer connections. In addition, a specific C++ program was developed to enrich the transfer line configuration with geometric and topological data, based on the characteristics of the machine tools available in a selected catalogue. Then, the enriched transfer line configuration was visualized using the collaborative VR tool GIOVE VF, thus giving the user the opportunity to evaluate the configuration in a 3D environment that can be shared, in principle, also with other user. Finally, the performance of the transfer line was evaluated by using another tool integrated in the ontology-based platform, namely Arena by Rockwell Automation. The researchers involved in the TNA have submitted an abstract titled Design of transfer lines: coupling optimization, simulation and visualization through an ontology based data model to the incoming conference CIRP CMS 2015 - 48th CIRP Conference on MANUFACTURING SYSTEMS.

Project Images :

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044