TNA project : Augmented Reality - An Improvement for Computer-Integrated Manufacturing

Acronym : 121-Augmented Reality - An Improvement for Computer-Integrated Manufacturing-Petruse

Project Lead : Radu Petruse From : Lucian Blaga University of Sibiu

Dates : from 21st October 2013 to 25th October 2013

Description :

Motivation and objectives :

To add extra value, gain knowledge and improve the research for my PhD thesis which is in the industrial engineering field. To study the implications of AR in the industrial field Also, presumably that AR will bring benefits in the industrial field, companies will be able to benefit from the results.

Teams :

The main directions of the scientific research activity are: • To achieve efficient and effective management of scientific research • Research orientation to medium and long-term needs of society • Integration to international research networks • To create a climate based on trust and scientific cooperation between the university’s professors and companies • Update and improve the university’s research equipment

Dates :

starting date : 21 October, 2013

ending date : 25 October, 2013

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/VFACTORY.IT.html

Recordings & Results :

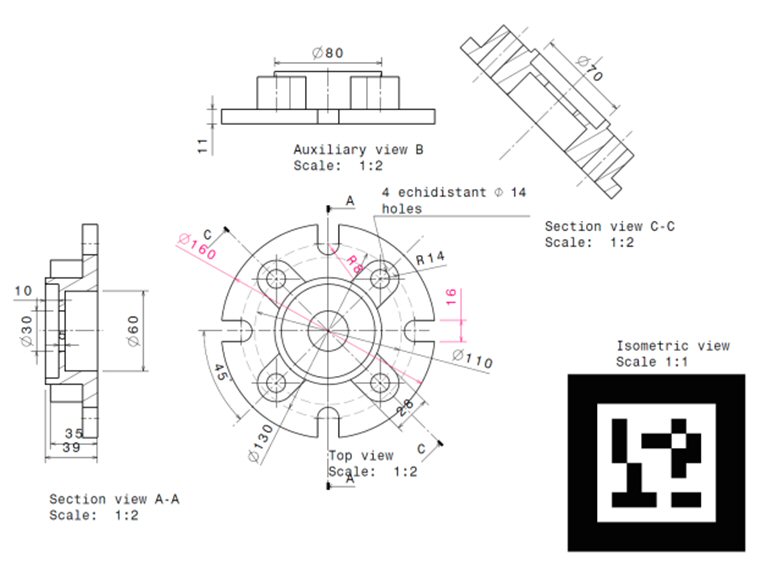

A study that has taken place in the first quarter of 2013 at the Faculty of Engineering from Sibiu has revealed that first year students have a lack of spatial visualization. Even when the same questionnaire was applied to a group of 91 students who underwent the descriptive geometry and technical design disciplines, the results were rather mediocre since students encounter problems during technical disciplines when they are requested to engage in design activities. When students are introduced to an industrial environment the lack of spatial visualization capability is a huge handicap for them and also for their employers. A contribute to the solution to this problem might be to use augmented reality (AR) in correlation with technical drawings.

Conclusions :

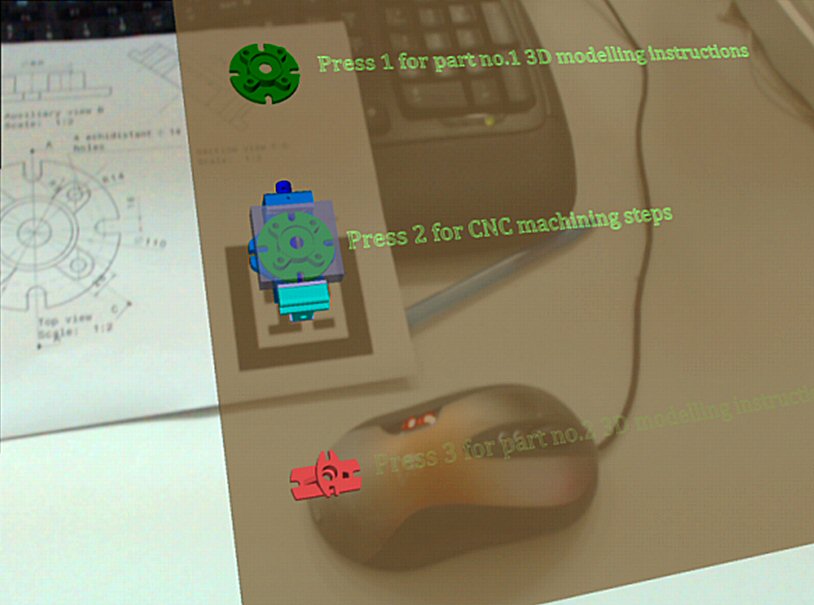

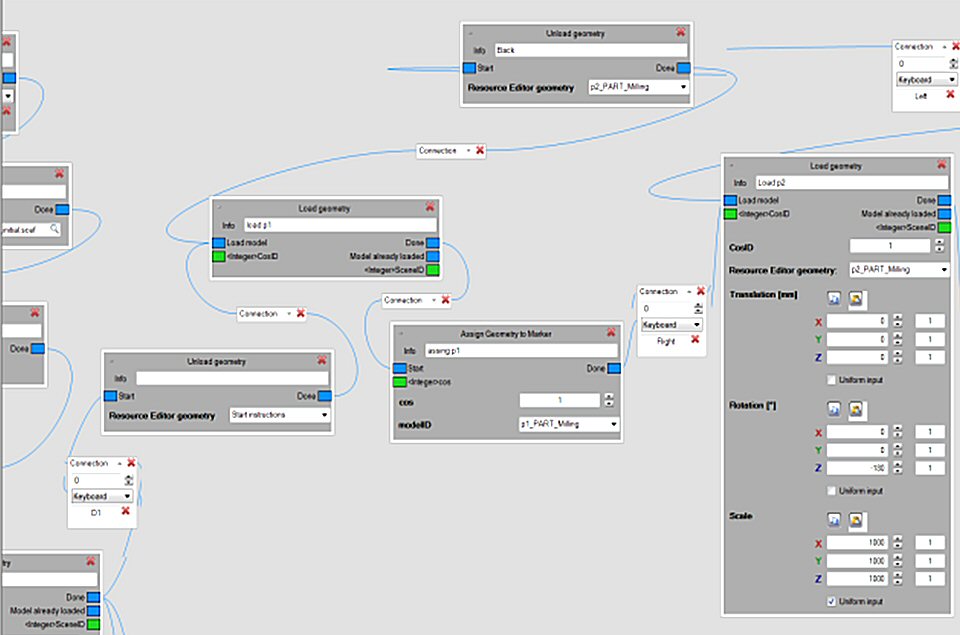

A first augmented reality (AR) environment for supporting users in learning mechanical drawing and design operations has been developed. In order to test this hypothesis, step by step instructions for 3D modeling in CAD software were developed based on two medium difficulty technical drawings. These instructions consist in a 3D model, superimposed over the technical drawing, for each step of the modeling process. The lack of spatial vision detected also influences CNC machining manufacturing processes. Because of this issue a step by step AR instructions for the machining process has been created in a similar way to the 3D modeling instructions. These instructions provide assistance to the AR user for the entire machining process. Such AR environment has been tested on some users at hosting institution and various comments about interface, visualization and use have been collected. Such overall comments will be then taken into account for the further developments of the AR environment itself.

Few images :

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044