Title : Robot path generation and visualization. Application for virtual industrial robots learning

Project Lead : Vytautas Bu?inskas From : Vilnius Gediminas technical university (None)

Dates : from -- to 2015-01-08 16:14:50

Description :

Motivation and objectives :

Present use of industrial robots raised natural problems for fast programming of their path. Versatility of articulated robots allows them to be used for transportation, positioning, as well as in different technological operations. They can just carry things in tough conditions such as: dirty, hot, wet, hostile environments. There are many spaces for it: CNC machining, manipulating in machining with ordinary tools, painting of complex (sophisticated) surfaces, surface preparations for painting, welding etc. At the present time more and more implementations of robot requires fast path generating, usually just by learning of robot with special haptic device. In technological conditions, where learning would be desired, but technically impossible, there exists a need to use means of virtual reality. Such conditions occur in painting booth with highly smelling resins, surface preparation for painting with intensive particle outlet, blaster chambers and many others. In addition it is necessary to point out, that all this programming of robot path should be performed fast, while industrial conditions requires so. There is a challenge to start create such virtual robot programming and simulating system.

Teams :

Department of Machine engineering is a department in Faculty of Mechanics, educating students, participating in scientific research and solving practical engineering and scientific tasks for industrial enterprises. Department actively participates in projects, during last 5 years there were more than 20 research and industrial projects performed. Consultancy - this is daily bread for our professors in field of different technologies, experimental testing and results evaluation.

Dates :

starting date : 15 October, 2014

ending date : 12 January, 2015

Facilities descriptions :

http://visionair-browser.g-scop.grenoble-inp.fr/visionair/Browser/Catalogs/MEXICO.FR.html

Recordings & Results :

Present use of industrial robots raised natural problems for fast programming of their path. Versatility of articulated robots allows them to be used for transportation, positioning, as well as in different technological operations. They can just carry things in tough conditions such as: dirty, hot, wet, hostile environments. There are many spaces for it: CNC machining, manipulating in machining with ordinary tools, painting of complex (sophisticated) surfaces, surface preparations for painting, welding etc. At the present time more and more implementations of robot requires fast path generating, usually just by learning of robot with special haptic device. In technological conditions, where learning would be desired, but technically impossible, there exists a need to use means of virtual reality. Such conditions occur in painting booth with highly smelling resins, surface preparation for painting with intensive particle outlet, blaster chambers and many others. In addition it is necessary to point out, that all this programming of robot path should be performed fast, while industrial conditions requires so. There is a challenge to start create such virtual robot programming and simulating system.

Conclusions :

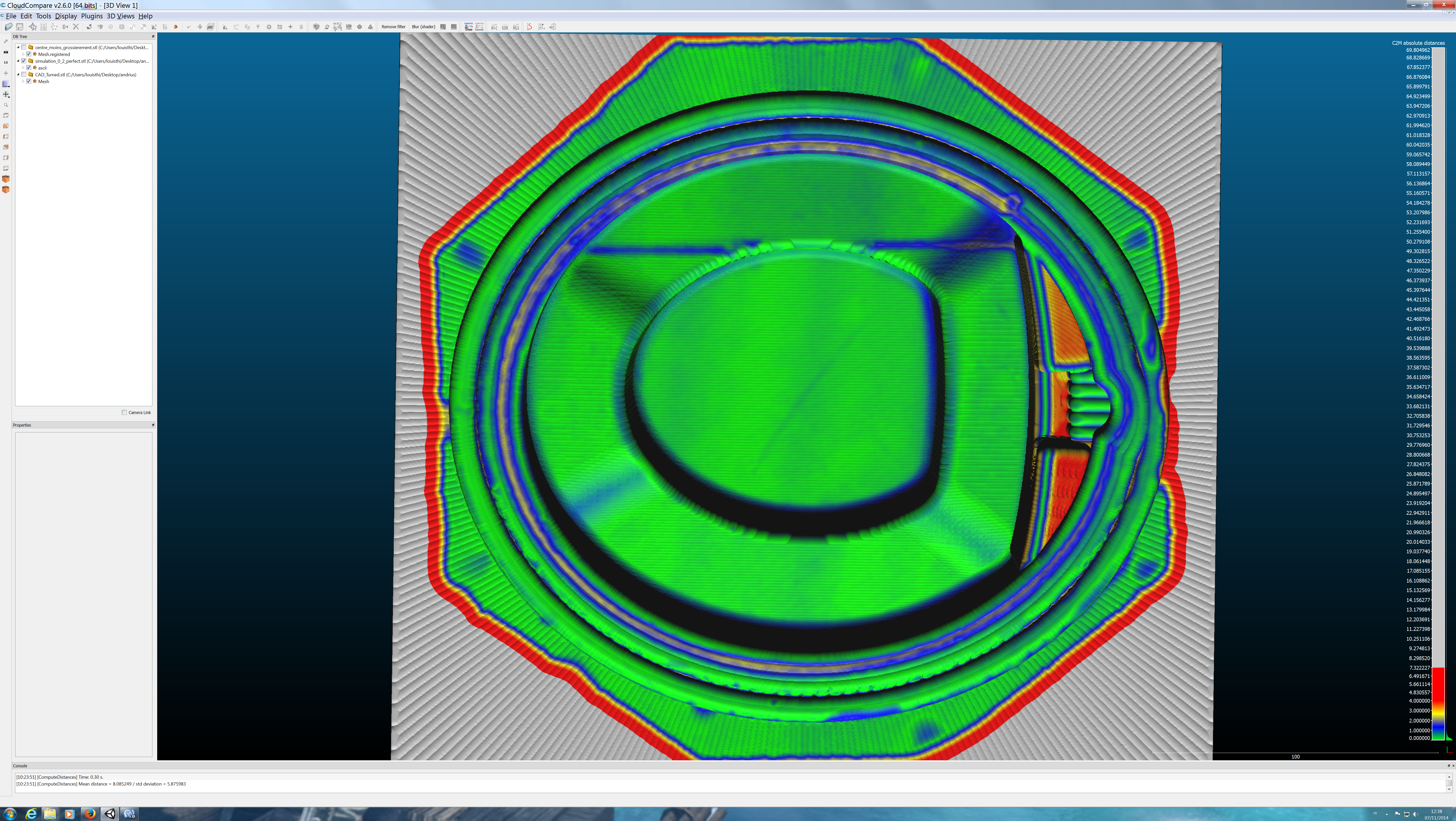

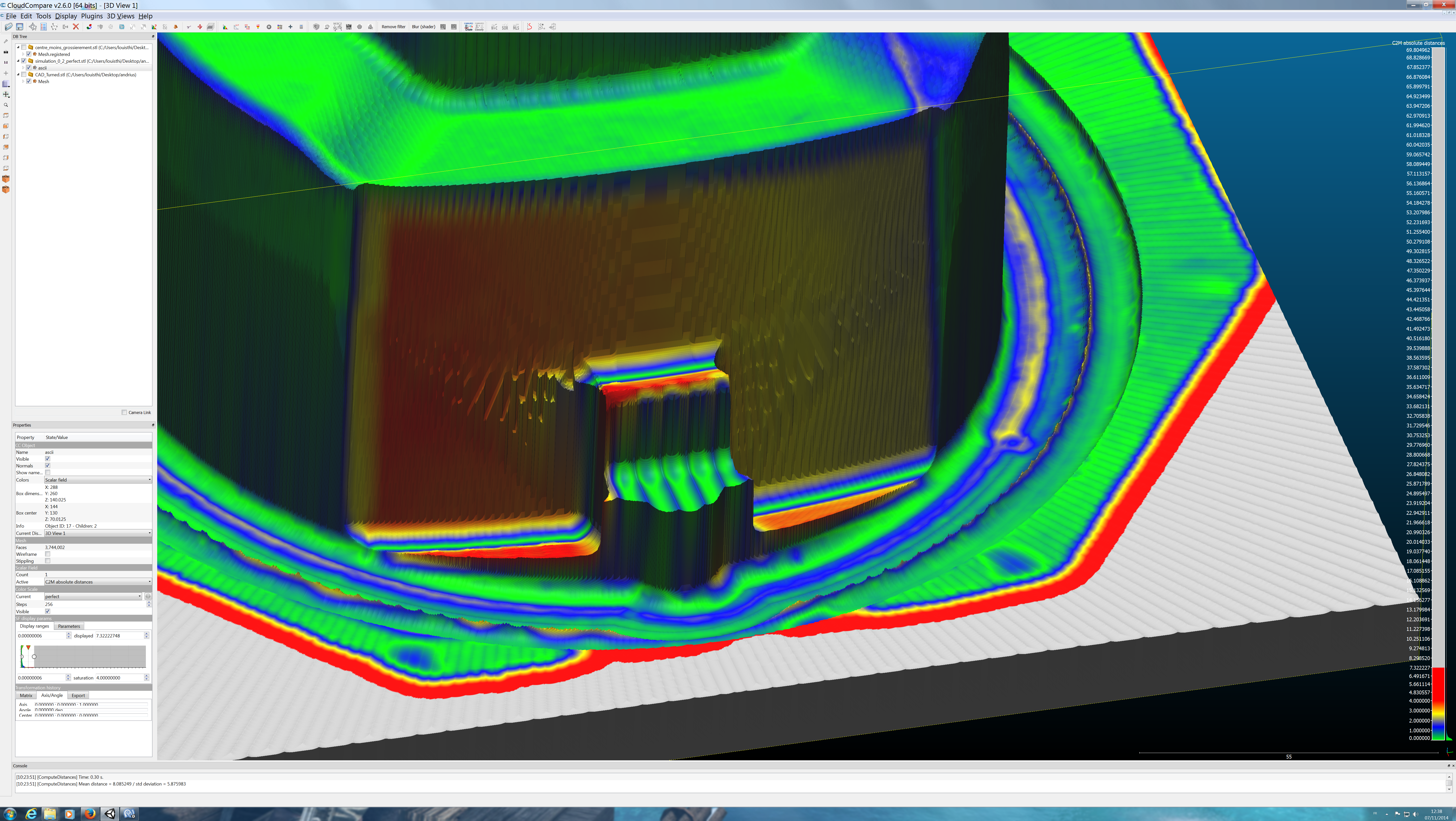

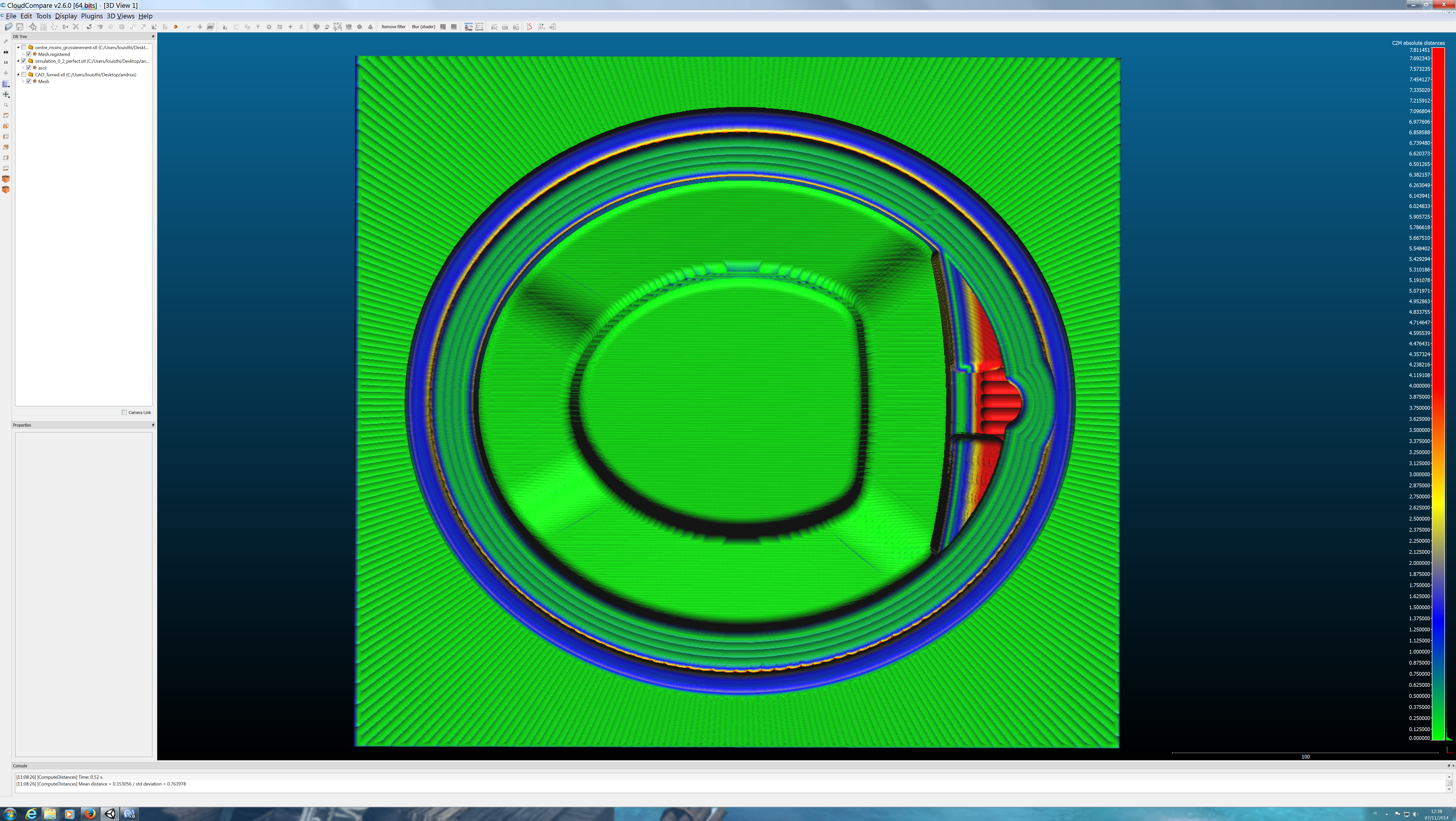

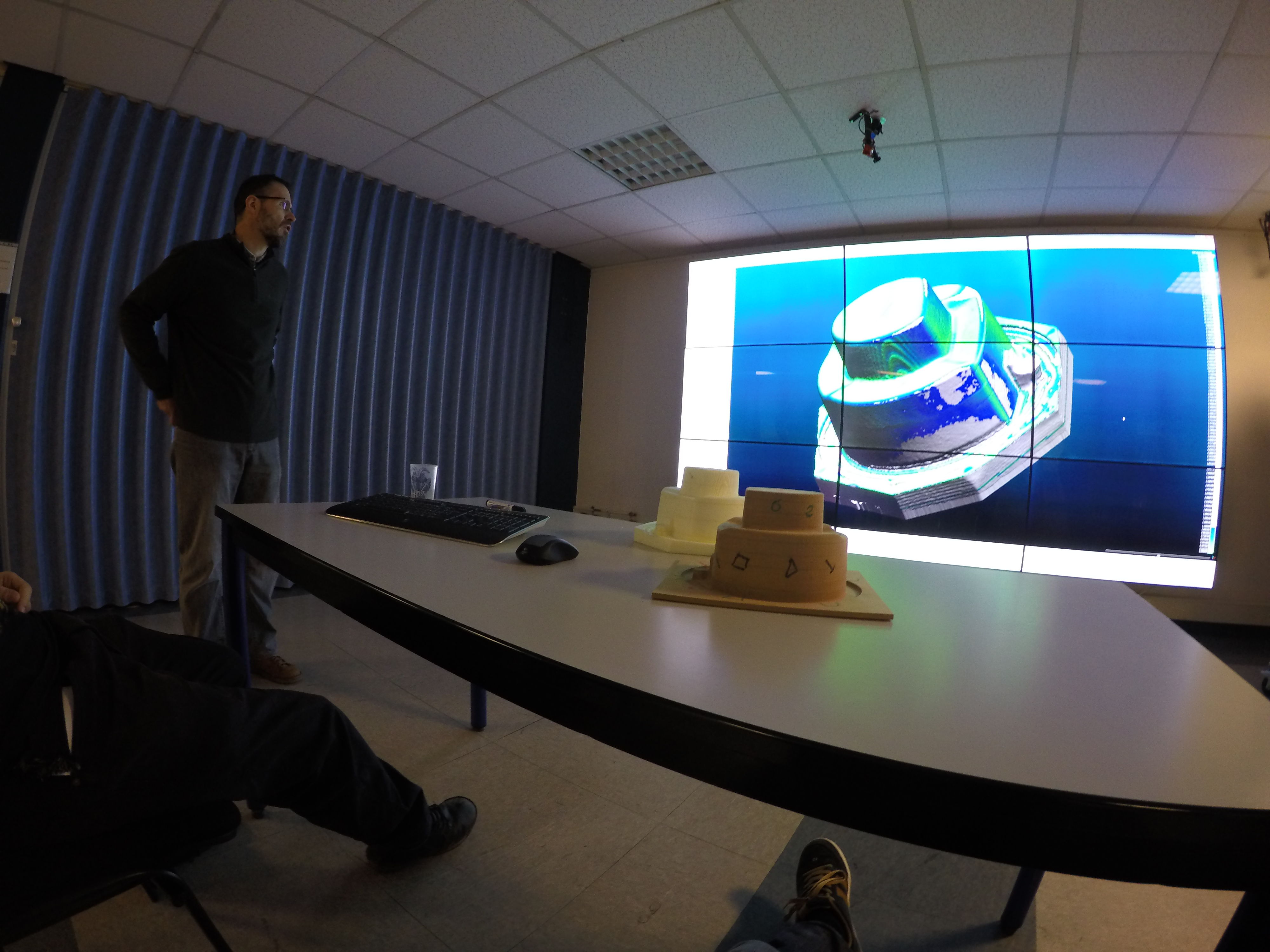

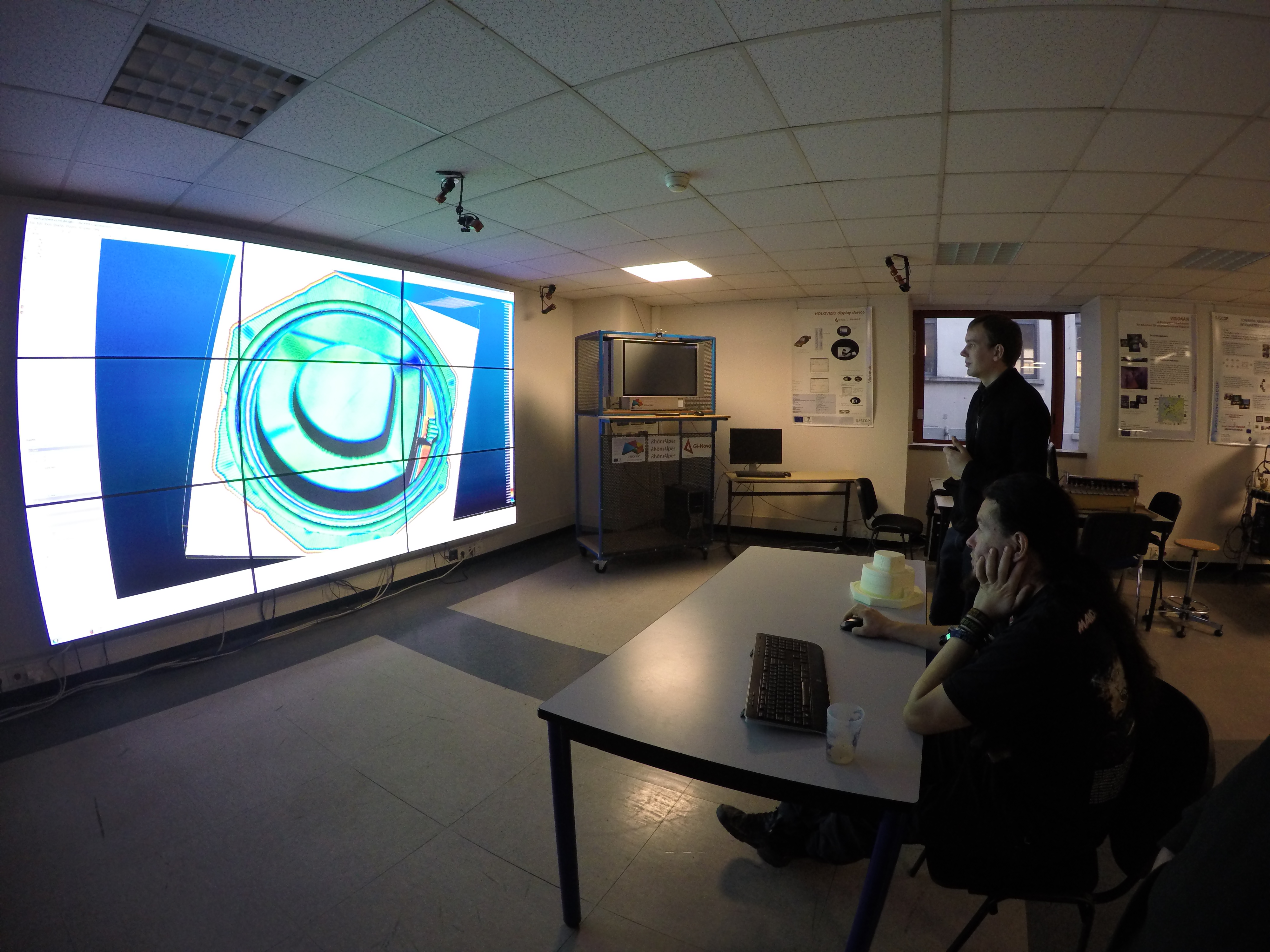

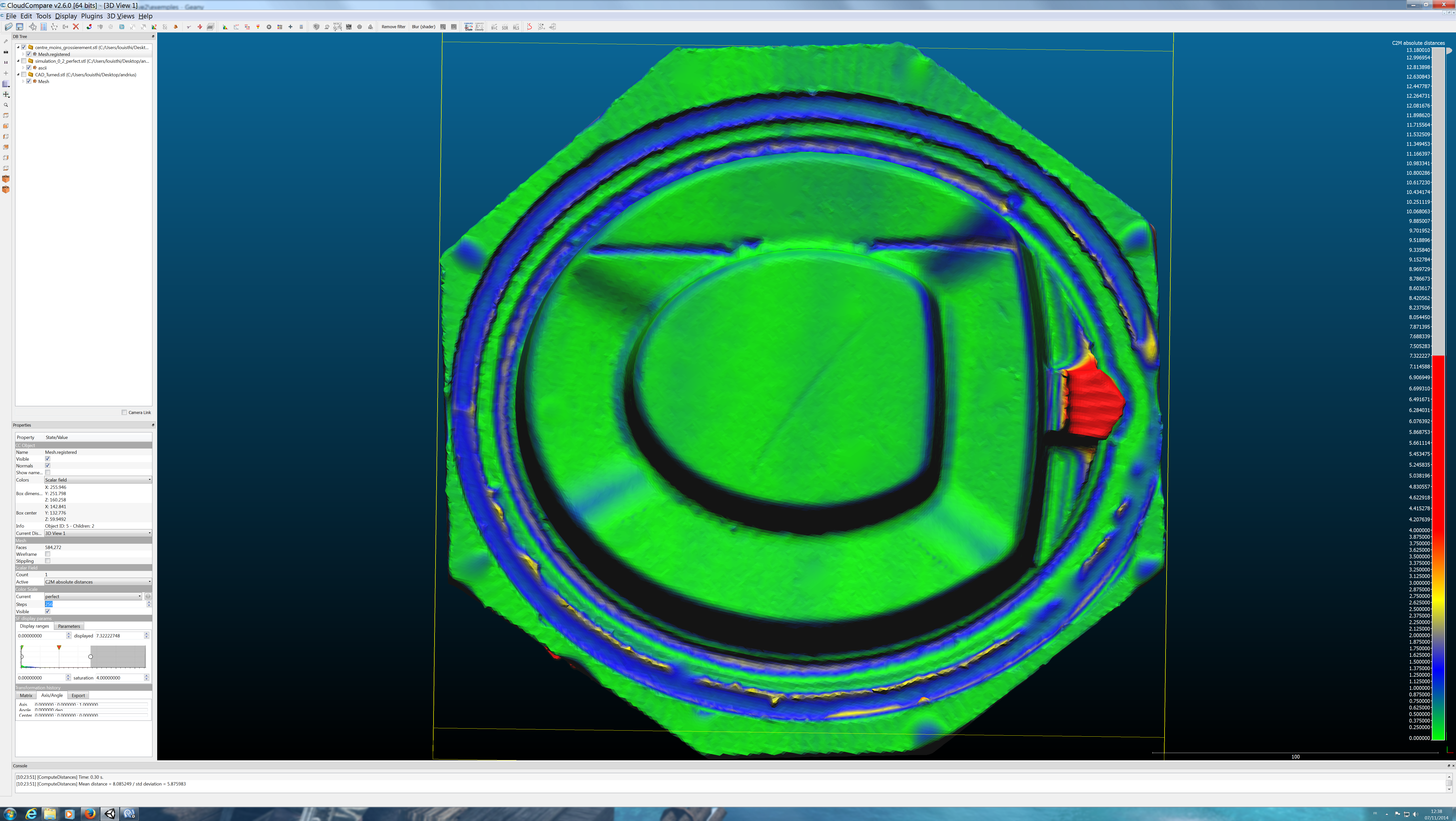

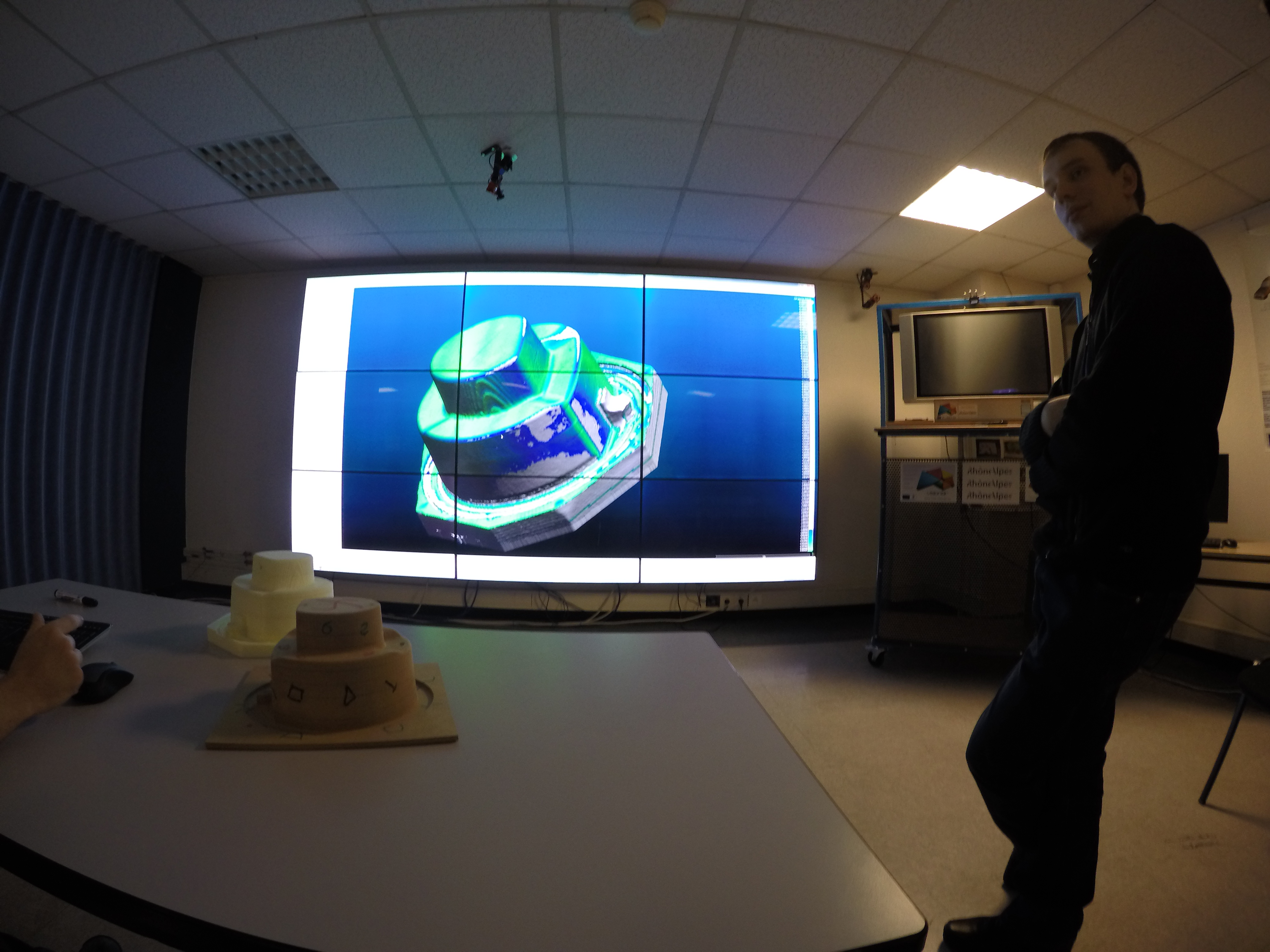

During the visit were examined the technical issues that affects the accuracy of model created by robot. Were carried out comparisons of the different models and obtained results suitable for publication in scientific article. It was also created new prototype of detail using different technologies. This provided an opportunity to compare different prototyping processes, and examine high-definition visualizations advantages in more details.

Project Images :

.

VISIONAIR / Grenoble INP / 46 avenue Felix Viallet / F-38 031 Grenoble cedex 1 / FRANCE

Project funded by the European Commission under grant agreement 262044

Project funded by the European Commission under grant agreement 262044